Nuclear Industry Must Change — Or Die

"Brace for impact."

The looming insolvency of Toshiba has set off a chain reaction of events that threatens the existence of nuclear power in the West:

— Britain’s plan to build six new nuclear plants — based on four different plant designs — in order to phase out coal by 2025 is now up in the air.

— Britain’s turmoil creates uncertainty for the French and Chinese nuclear industries — as well as for another Japanese company, Hitachi — that had won contracts to build other British plants.

— In response to Toshiba’s failings, one of India’s leading nuclear policy experts is calling for the government to scrap existing plans with Areva, Westinghouse and Russia’s Rosatom, and "Make Nuclear Indian Again" by scaling up the country’s indigenous design.

— On Wednesday Mitsubishi’s CEO told the Financial Times that the company is not considering a merger with Toshiba. The reason? Toshiba's nuclear design "is a totally different technology" from Mitsubishi's.

— A proposal by Southern Company to build a third nuclear plant based on Toshiba’s Westinghouse AP1000 design in Georgia is increasingly unlikely.

The Japanese and French governments will be compelled to act for economic reasons — their nuclear industries are too important to their economies to fail. The Japanese government has always played a strong role in shaping the direction of its industries, including nuclear, while the French nuclear industry is entirely government-controlled.

Even though it lacks its own nuclear industry, Britain is emerging as the strongest of the three nations because it has a significant number of planned nuclear plants that involve Japanese and French companies, and is a big player in a buyer's market.

The new Conservative government of Theresa May has expressed more interest in industrial policy than prior Conservative governments, and has already begun talks with the Japanese government about the UK government coming in as an investor on two of its planned plants.

The question is whether anyone in the three governments will have the vision and strength to make the right choices. The right choices will be the most difficult ones because they will require standing up first to the nuclear industry and next to ideologues on the Left and the Right.

But crises bring opportunities and there are large ones for reformers within the industry and within governments to do what should have been done 40 years ago: standardize designs, reorganize and consolidate the industry, and implement a vision to scale up plants while bringing down costs.

But before doing any of that, policymakers and the public must understand why Toshiba and Areva failed.

Why Nuclear is Failing

1. Lack of Standardization and Scaling

“Everything you described in your article was true for nuclear plants built in the 1970s,” an industry veteran told me.

In my investigation, I described how Toshiba’s Westinghouse AP1000 design was radically new — it had never been tested and indeed wasn’t even complete before construction began.

And yet when it came time to build two of them in Georgia and South Carolina, all parties were afflicted with a kind of historical amnesia.

“No one involved seemed to fully appreciate just how difficult it would be to build new reactors, especially the AP1000 — a ‘first of a kind’ design,” reports the Financial Times.

It’s not unusual for big construction and manufacturing projects to go over time and budget.

Consider the San Francisco Bay Bridge. After an earthquake in 1989 caused part of it to collapse, California officials decided to replace the entire eastern span.

Construction started in 2002 and was supposed to cost $1.5 billion. The project was afflicted with challenges. In 2009, steel rods flew off the span and hit at least two cars. Faulty bolts were discovered. The problems delayed the opening by four years and cost $6.4 billion — four times more than what had been estimated.

Or consider the Boeing "Dreamliner" jet aircraft. The FOAK arrived three years late, in 2011. Immediately things went awry. Engines failed along with fuel pumps, computers and wings. Lithium batteries caught on fire. The problems were so bad that the Japanese government launched its own investigation.

Now consider that building a nuclear plant isn't like building a bridge or a jet plane — it's like building a bridge and a jet plane at the same time.

Except it's not. It’s much harder than that.

The reason has to do with scale. Where Boeing is making 10 aircraft per month — allowing everyone involved to become more efficient and produce planes faster — it takes nuclear plant construction companies up to 10 years to build one plant.

Boeing knows the importance of standardization. The company is losing money on every Dreamliner it makes, and says it hopes to make money after selling 1,100 of them. Thus, when faced with a rash of problems in 2012, Boeing didn't give up on the Dreamliner design — it fixed the problems.

The response from the nuclear industry to such problems would have been to invent yet another nuclear plant design complete with promises of greater safety and lower cost. And yet what makes nuclear plants safer and cheaper to build and operate is experience, not new designs.

Wrote Richard K. Lester and Mark J. McCabe:

In the United States, a sizable operating performance penalty has been paid both as a result of the diffusion of several types of LWR technology and because of the relative scarcity of multiunit sites caused by the fragmented structure of the electric utility industry. In France, by contrast, performance has benefited from the very high degree of plant design standardization and the prevalence of multiunit siting.

What the constant switching of designs does is deprive the people who build, operate and regulate nuclear plants of the experience they need to become more efficient.

Why then does the industry keep doing it?

2. The War on Nuclear

To some extent, the 40-year obsession with innovative new designs is a consequence of an industry dominated by the engineers — the project architects — rather than by the construction firms.

But Boeing and Airbus are companies headed by engineers who don’t make the nuclear industry’s mistakes. Why?

The answer in part is that Boeing doesn’t have to deal with a powerful, $500 million annual lobby that does everything it can to deliberately make nuclear expensive.

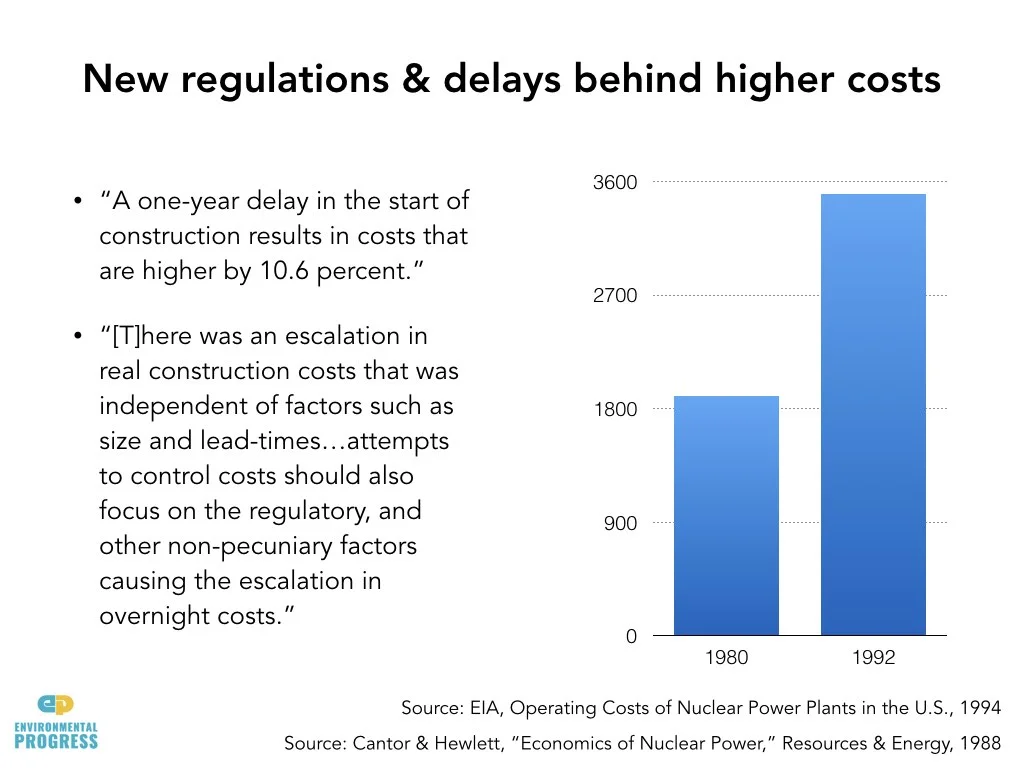

NRDC, Sierra Club, Greenpeace, UCS, and myriad state and local groups have spent 50 years frightening the public with pseudo-science, suing utilities, subsidizing the competition, and winning regulations that do nothing for plant safety.

On the one hand, the nuclear industry responded brilliantly to these attacks. After the anti-nuclear movement landed a decisive blow against the industry in 1979, with the meltdown at Three Mile Island book-ended by the release of the hysterical film “China Syndrome” and “No Nukes” concerts, the industry got its act together.

Over the next 30 years the industry worked diligently to better train its workers and create a culture of safety that resulted in an extraordinary rise in plant efficiency from about 50 percent to over 90 percent today.

But the industry also responded by creating new and untested designs: Westinghouse’s AP1000 and Areva’s EPR.

The problem of serial design-switching is compounded by the vanishingly small number of nuclear plants being built. Just 60 plants total are currently under construction — most of different designs.

The Koreans, by contrast, prioritized efficient construction over innovative new designs, and are now leading the global competition to build new nuclear plants.

3. Too much focus on machines, too little on human beings

Areva, Toshiba-Westinghouse and others claimed their new designs would be safer and thus, at least eventually, cheaper, but there were always strong reasons to doubt such claims.

First, what is proven to make nuclear plants safer is experience, not new designs. Human factors swamp design.

The same is true of aircrafts. What made air travel safe was many decades of training and experience by pilots, air traffic controllers, and regulators — not radically different jet plane designs.

In fact, new designs risk depriving managers and workers the experience they need to operate plants more safely, just as it deprives construction companies the experience they need to build plants more rapidly.

While Boeing has touted the Dreamliner as a kind of breakthrough, it was an incremental improvement on the same jet planes we’ve been flying on since the 1950s, and did little to change the procedures of pilots and flight attendants.

To be sure, continuous improvement of jet plane technologies has contributed to making flying safer than ever.

But the key factors were executive-level commitment to risk reduction, a company-wide safety culture, better emergency trainings, inspections and accident investigations.

Second, how do you make a technology that almost never harms anybody any safer than it already is?

Fossil fuels operating normally kill far more people than nuclear plants do when they malfunction.

And given such tiny health impacts, it’s simply not clear that making plants any safer is actually possible. Long time horizons and small sample sizes will likely make it impossible to ever know — scientifically — that newer plant designs are safer.

Advocates of new designs, including the EPR and AP1000, will acknowledge this point, but point to their enhanced safety, such as the EPR’s double containment dome, the AP1000’s back-up water system, or meltdown-proof fuel-coolant mixtures.

But the Nuclear Regulatory Commission has already ruled that all new nuclear plants will be subject to the Aircraft Rule.

And containment domes are not as large of an expense as is sometimes suggested. A 2012 Black and Veatch study estimated that for the AP1000 the reactor island was just 13 percent of total plant costs. And the reactor island’s actual share of costs would be lower given the $10 billion in cost overruns of the two US AP1000s.

The key takeaway from the Toshiba and Areva debacles is that the cost overruns due to construction delays from building a highly regulated FOAK nuclear plant swamp any savings from modestly smaller amounts of necessary equipment.

Finally, the overwhelming amount of harm caused by accidents are due to fear and panic, not radiation exposure.

What made Three Mile Island, Chernobyl and Fukushima the three worst nuclear accidents wasn’t the radiation released. The fire at an innovative gas-cooled reactor in Windscale, England, in 1957, and the partial meltdown of a sodium-cooled reactor near Detroit in 1966, were both far worse than Three Mile Island.

What made the more famous accidents harmful was how local and federal governments panicked and triggered dangerous over-evacuations. What they should have done was told local residents to simply “shelter in place” — as is done for things like tornadoes — until the accident was dealt with.

Contrast that to the handling of jet plane accidents.

Passengers on Sully's flight brace for impact by sheltering in place.

In the recent film “Sully,” based on a real event, an Airbus 320 loses both of its engines to bird strikes in just five minutes. With all power gone, the pilot has seconds to act. Can he make it back to La Guardia airport in New York? Or should he attempt a water landing in the Hudson river?

Captain Sully chooses the latter. He tersely announces, “Brace for impact,” at which point the flight attendants in unison begin a kind of creepy, hypnotic chant: “Brace! Brace! Heads down! Stay down! Brace! Brace!...”

The passengers comply. They are frightened, and some scream, but they stay seated. They tuck their heads and some put hands on the seat in front of them. In other words, they shelter in place.

And everyone survives.

How to Save Nuclear

1. Consolidate or Die

Two companies dominate production of large-bodied jet planes: Boeing and Airbus.

Large, complicated projects like building a jet plane or a nuclear plant require very large, upfront investments that only large, well-capitalized entities can back — like an electric utility, or Boeing, which invested $32 billion making the Dreamliner.

If nuclear is going to survive in the West, it needs a single, large firm — the equivalent of a Boeing or Airbus — to compete against the Koreans, Chinese and Russians.

There will never be as many nuclear plants as jet planes, especially not during a time of low overall demand for electricity. As such, economies of scale must be achieved more rapidly.

One of the keys is making both construction and operation as efficient as possible.

Many of the big global nuclear players offer to build and operate the plants. That's what the Korean company, KEPCO, has done in the United Arab Emirates (UAE).

The four-reactor nuclear plant KEPCO is building is in UAE on-time and appears to be on-budget. In January, the UAE awarded KEPCO with a 60-year, near-$50 billion contract to operate and maintain the plants it built.

I was told by someone in the industry that KEPCO treated the construction part of the work as a loss-leader in order to get the more lucrative operation, maintenance and refueling contract — and perhaps to advertise its construction prowess to other nations.

The Airbus of nuclear should be run by someone with significant experience in nuclear plant construction — since that's where the cost savings (and overruns) come from — not engineering.

To some extent, consolidation is already happening. In 2006, Toshiba bought Westinghouse and Mitsubishi partnered with Areva, while in 2007, Hitachi partnered with the GE nuclear division.

Toshiba recently bought the construction firm hired to build the AP-1000 Vogtle plant, but with the latter deal, the consolidation came too late. It was done in response to, not in anticipation of, future construction and manufacturing delays.

Of course, consolidation on its own is not enough, as Areva learned. There must also be standardization, scaling and social acceptance. Consolidation is essential to achieve the repetitions required for cost reductions. And a planned scaling-up of nuclear is the key to achieving those repetitions.

2. Standardize or Die

First, the new Boeing or Airbus of nuclear should build a single design. Standard-setting is a traditional role of government, and in the past has been a huge aid in helping industries consolidate, grow and achieve continuous improvement.

The UK has key role to play here. The heterogeneity of its planned reactors is astonishing:

- AP1000 x 3 for Moorside

- EPR x 2 for Hinkley Point C, EPR x 2 for Sizewell C

- Hitachi ABWR x 2 for Wylfa Newydd, ABWR x 2 for Oldbury B

- Hualong-1 x 2 for Bradwell

The UK should scrap all existing plans and create a new plan from a blank piece of paper. All new UK nuclear plants should be of the same design.

Second, the criteria for choosing the design should emphasize experience in construction and operation, since that is the key factor for lowering costs.

Reprocessing waste should be off the table. It is unnecessary and adds to the costs.

Some emphasis should also be on mass-manufacturing modules, something the Koreans are also pursuing.

But what both Toshiba and Areva failures underscore is that all new nuclear plants, however much they are going to be manufactured, are going to require construction according to the exacting standards of strict regulators, and it was that kind of construction that helped destroy not just one but two of the world’s largest nuclear companies.

Third, the plants should be constructed sequentially so that managers and workers in Airbus Nuclear can learn from experience.

Fourth, the firm should have strong financial incentives for reducing costs.

Fifth, the program should include a significant increase in funding to test alternative reactors.

The record here is clear: governments only invest significantly in demonstrating new nuclear reactor types when their nations are building new nuclear plants. And with good reason: people believe there is a future for nuclear.

It works the same way in reverse. Long before they had achieved their goal of shutting down existing plants, anti-nuclear activists avidly sought to cut funding for nuclear innovation. They won a big victory in 1982 when Congress cut funding for the Clinch River fuel processing project. And they won another in 1993 when Congress cut funding for the integral fast reactor.

Funding for the experimental molten salt reactor developed at Oak Ridge in the late 1960s was cut before it could ever become a test reactor. The U.S. Atomic Energy Commission estimated that building one would cost $10 billion (in 2016 dollars), and noted that past tests usually cost twice what had been estimated.

A long-term, global build-out of standardized nuclear plants is the only way in which states will invest the billions needed to test radically different designs.

3. Scale or Die

What's behind the crisis facing nuclear generally and Toshiba in particular is the utter lack of certainty about any future nuclear plant builds — including those under construction.

Nations must work together to develop a long-term plan for new nuclear plant construction to achieve economies of scale. Such a plan would allow for certainty, learning-by-doing, cost declines and lower financing costs.

Risk and rewards should be pooled. Cost savings achieved through experience should be shared along with the cost overruns of the first few plants.

Governments should invest directly or provide low-cost loans. While this will inevitably be decried by anti-nuclear groups, the truth is that the U.S. and Europe have been subsidizing wind and solar for decades. In Illinois and California, subsidies for wind and solar have played a key role in threatening nuclear plants with premature closure, undermining clean air and climate goals.

Some basic fairness is in order. This starts with investment and financing as well as support for nuclear plants at risk of premature closure due to our discriminatory subsidy regime.

Others might wonder why nuclear energy should be supported when Boeing and Airbus flourished without government help. But the truth is that they didn’t: last year the World Trade Organization says Boeing and Airbus received billions in government subsidies — up to $22 billion worth for Airbus alone.

UK Labor leaders have already called for direct government investment to save the plants:

“The delay we’re seeing under the Tories is leaving thousands of nuclear workers uncertain about their future,” the shadow Labor secretary said on Wednesday. “Public investment in nuclear energy would bring huge benefits through the nuclear supply chain and energy security.”

Plus, financing is the key to opening up the global market — something that is in the entire industry’s interest.

Vietnam recently cancelled plans to build nuclear plants and is now planning to build coal plants instead. Someone close to the situation told me that had foreign nations financed the nuclear plants, they would have gone forward.

And the quantities of financing — not development aid — are trivial considering the potential benefits to nuclear supplier nations, especially when the financing is spread out over 30 years and is shared by UK, Japan, France and the United States.

And such financing would offer a decisive advantage to the Airbus of nuclear over its competitors, allowing it to win contracts and provide the certainty everyone in the industry needs.

For such an effort to work, it would need widespread support that lasts for many decades. That will require that national governments work together to increase public demand and social acceptance of nuclear. Toshiba and Areva show that declining social acceptance drives demand for unnecessary regulations, as well as the industry's constant changing of designs.

Japan’s nuclear industry cannot survive so long as public opposition is preventing the restarting of shuttered nuclear plants.

The Japanese government and industry leaders must overcome their shame and seek help from allied nations in overcoming the public’s continuing radiophobia in response to Fukushima.

What’s needed is an independent, serious and sustained effort by health and medical professionals to help Japanese and other publics to overcome fears based on grossly unscientific information.

France, Canada and most recently Vietnam all show that this can be done.

And as an analogy, there is much more to be learned from efforts to increase support for vaccinations among skittish parents. There is an aggressive and effective effort to educate the public about vaccines that, for the most part, still works. In response to a recent measles outbreaks, for example, California started requiring students be vaccinated to attend public schools.

If millions of parents will inject their children with the polio virus because they understand that it is a weakened version of the one that cripples and kills, they are capable of understanding that nuclear plants are the safest and cleanest way to make electricity.

The truth is that human beings around the world have been victimized by fake news about nuclear power since the late 1960s. When most people learn the basic facts about nuclear they become far more supportive of it.

And yet neither governments nor industry have ever, in the 50 years of nuclear energy, made a serious effort to provide those facts.

What that means is that there is enormous potential to touch hearts and change minds, just as many of ours were upon learning why nuclear is essential to mitigating climate change.

If millions of parents will inject their children with the polio virus because they understand that it is a weakened version of the one that cripples and kills, they are capable of understanding that nuclear plants are the safest and cleanest way to make electricity.

Now Change

The crisis that threatens the death of nuclear energy in the West also offers an opportunity for a new life.

When you consider that the nuclear industry has for 40 years often done the exact opposite of what’s known to work, it’s a small miracle that nuclear is still 11 percent of global electricity, instead of zero.

Everything that’s wrong — the proliferation of designs, the delay in project starts, efficient Korean competitors, low demand, low social acceptance — is something that can be made right.

We can learn from the Koreans. We can standardize design. We can finance the necessary scale. We can go back to Vietnam with a better deal. And we can increase public acceptance.

Policymakers have a special role to play. They must seek out reformers and change agents within an industry that is dominated by the same kind of thinking that led to today’s crisis. They must reach out to their counterparts in other nations. And they must stand up to ideologues peddling pseudo-science on the Left and pseudo-economics on the Right.

Ultimately new leadership with a new vision and plan must emerge from within the nuclear industry. Toshiba has seen a succession of leaders pitching what is fundamentally the same approach. It’s not clear that Areva has yet learned the lessons from its EPR debacle, or whether anyone has really started to clean house.

But, happily, Toshiba and Areva are not the only two companies capable of exercising the leadership required to save the world’s most important environmental technology from being consigned to the long-term waste repository of history.